About G3:

Global Graphene Group, Inc. (G3) is a Dayton, Ohio, USA-based advanced materials and battery technology company. G3 researchers discovered and patented graphene in 2002, two years before Nobel Physics Prize winners, Drs. A. Geim and K. Novoselov, are credited with their “discovery” of graphene in 2004 [Science 306, 666–669 (2004)]. G3 is focused on commercialization of next-generation EV batteries and its fully-owned subsidiary, Angstron Materials, Inc. (AMI), provides graphene and selected non-battery products.

Currently, G3 has 490+ patents specifically related to advanced batteries and it is ranked at the forefront in IP ownership among all the battery start-ups in the world. G3 was recently recognized as one of the two US leaders in solid-state batteries (Solid-State Li-ion Batteries with Inorganic Solid Electrolytes Patent Landscape 2021 – KnowMade). Based on the data compiled in 2021 by KnowMade, a French IP landscape analyzer, G3 had a total of 41 patent families related to solid-state lithium batteries with inorganic solid electrolytes.

Problems Associated with Current Lithium-ion Batteries:

The EV industry is looking for batteries that can deliver four key features: increased energy density for extended driving range on one battery charge, fire safety, fast charging and lower cost. According to Dr. Bor Z Jang, co-founder and CEO, the battery technologies developed by G3 are aimed at addressing these EV battery challenges. Today’s EV batteries are largely based on lithium-ion cells, wherein each cell is typically composed of an anode (negative electrode), a cathode (positive electrode), a separator that electrically isolates the two electrodes, and a liquid electrolyte that provides a medium through which lithium ions can migrate back and forth between the anode and the cathode. The EV battery issues are directly related to the anode, the cathode, and the electrolyte used.

Anode and Cathode Materials of Current Lithium-ion Batteries:

The incumbent anode material is graphite, which stores lithium ions at a theoretical specific capacity of 372 mAh/g (practically, 340-360 mAh/g). A lithium-ion cell, having a graphite anode and a lithium nickel cobalt manganese oxide cathode (NCM, 175-210 mAh/g), provides a specific energy of typically 220-260 Wh/kg. Alternatively, another common cathode material used is lithium iron phosphate (LFP). However, since LFP has a lower capacity (150-160 mAh/g), the energy density achieved is typically lower than 200 Wh/kg. For perspective, the EV industry is looking for a reliable battery capable of delivering a specific energy of 350-450 Wh/kg.

Replacing Graphite with G3 ’s Silicon-Rich Anode Materials for Improved Energy Density:

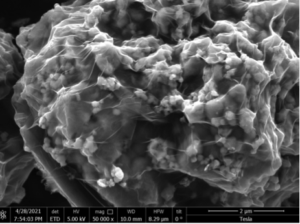

By replacing the graphite in an anode with silicon (Si, which has a theoretical specific capacity of 3,580-4,000 mAh/g), one can obtain a cell having the desired energy density of 350-400 Wh/kg. G3 has improved silicon anodes by developing a cost-effective graphene/silicon composite anode material that enables a significantly higher energy density (e.g., a 40% increase in the EV driving range) at a 15% reduction in the cell cost ($/kWh). Graphene has proven to be effective in resolving the battery capacity decay problem caused by repeated volume expansion/shrinkage of silicon. G3 provides silicon-rich high-capacity anode materials (Figure 1 below) that exhibit the highest performance-to-cost ratio and make it possible to significantly extend the EV driving range on one battery charge.

G3 is ready to expand its current production capacity of Si-rich high-capacity anode materials from 25 metric tons/year to thousands of metric tons in 3 years.

(Figure 1; G3’s Graphene-Protected Si Anode Particle Material)

Replacing Graphite with G3’s Protected Lithium Metal for Improved Energy Density

Alternatively, graphite may be replaced with lithium metal (Li) in the anode to obtain a lithium metal battery, which is commonly believed to be capable of delivering an energy density in the range of 400-500 Wh/kg, depending upon the cathode material used. However, such a potential benefit does not come without challenges. During the charge-discharge cycles of a lithium metal cell, needle-like growths called “lithium dendrites” can occur in the lithium metal in the anode. These dendrites can penetrate through the separator and reach the cathode side and cause internal shorting, which poses fire and explosion hazards. In addition, repeated reactions between the lithium and the liquid electrolyte will continue to consume both the active lithium ions and the liquid electrolyte, leading to rapid capacity decay. While these technical issues have thus far impeded the practical utilization of lithium metal batteries to replace the conventional lithium-ion batteries for EV applications, G3 has developed several lithium metal protection strategies to address these issues.

Flame-Resistant Electrolytes for Improved Safety

The safety of lithium-ion or lithium metal batteries hinges upon the availability of a non-flammable electrolyte. The liquid electrolytes commonly utilized in current lithium-ion batteries contain a lithium salt dissolved in an organic solvent, which contains volatile molecules that can catch fire. In contrast, solid-state electrolytes, comprising no volatile chemical species, are being developed for both lithium-ion and lithium-metal battery types. Further, solid-state electrolytes, when used as a separator, can significantly reduce or eliminate the lithium dendrite issues. However, solid-state electrolytes bring along other types of challenges to a battery designer, including a higher internal impedance (hence, lower power), lower anode or cathode active material proportion (hence, lower-than-expected energy density), and a higher manufacturing cost. The latter challenge is largely a result of the need to develop a new process and new equipment for producing the solid-state separator and for assembling the required components into a battery cell.

G3 has developed a versatile solid-state electrolyte technology that overcomes the issues commonly associated with the state-of-the-art solid-state electrolytes. G3’s electrolytes (trademarked as FireShield TM , Figure 2 below) are process-friendly and compatible with current lithium-ion cell manufacturing processes. Specifically, G3’s disruptive material process technology will enable all current lithium-ion cell manufacturing facilities to produce solid-state or quasi-solid electrolyte-based safe lithium batteries below) without the need to change existing equipment and facilities. This implies that the lithium-ion battery industry can readily enjoy the benefits of solid-state, lithium metal batteries right away, not having to wait 5-10 years.

G3’s battery technology will provide significant benefits across multiple battery parameters, including capacity, operating life, and safety, while minimizing cost. G3 is also ready to commercialize the graphene-protected lithium metal anode technology, which is essential to the accelerated emergence of a solid-state lithium metal battery industry. Further, the process-friendly electrolytes are also ready to solidify G3’s leadership position in converting the entire lithium battery industry into a quasi-solid and solid-state status.

Figure 2: Traditional electrolyte (left) vs. G3 Fireshield electrolyte (right)

Dr. Bor Jang, Co-founder, CEO & Chief Scientist at Global Graphene Group received his master’s and PhD degrees in Materials Science from MIT. Dr. Jang was the former Dean of the College of Engineering and Computer Science at Wright State University and former Head of the Department of Mechanical Engineering at North Dakota State University. Dr. Jang was Professor and the Materials Engineering Graduate Program Director at Auburn University. He was a Fulbright Scholar and Visiting Professor (and an Overseas Fellow of the Churchill College) with the University of Cambridge (1991-1992) in the UK. Dr. Jang was elected as a member of the US National Academy of Inventors (NAI) in 2019. Dr. Jang has more than 800

patents to his credit. Most notably, Dr. Jang filed the world’s first patent application on graphene in 2002.

Dr. Aruna Zhamu, Co-founder & Chief Technology Officer at Global Graphene Group, received her master’s degree in chemical

engineering from the School of Chemistry and Chemical Engineering of Inner Mongolia University. She holds a PhD in materials science and engineering from Beihang University. She was a post-doctoral researcher at North Dakota State University. Dr. Zhamu holds over 480 US patents (issued or pending) plus 200 foreign patents, which are related to graphene production, graphene applications, supercapacitors, fuel cells, batteries, and composite materials. Dr. Zhamu is the only female scientist to hold more than 150 US patents.

For more information, please visit G3’s website at www.theglobalgraphenegroup.com.

The post Global Graphene Group (G3) – an IP Leader in Solid-State Batteries for Next-Gen Electric Vehicles appeared first on The Global Graphene Group.